Non-Standard Injection Molding In Automotive Industry Plastic Injection Molding Machine Parts

| Place of Origin | China |

|---|---|

| Brand Name | BAITO |

| Certification | ISO9001 |

| Model Number | Non-standard |

| Minimum Order Quantity | 1 pcs |

| Price | Negotiates |

| Packaging Details | Packed by sponge with plastic bag, Outpacking:wooden box or upon request. |

| Delivery Time | 5-8 workdays |

| Payment Terms | T/T |

| Supply Ability | 300 Piece/Pieces per Month |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Place Of Origin | Guangdong. | Size | Non-standard/standard. |

|---|---|---|---|

| Shaping Mode | Plastic Injection Mould. | Feature | High Precision. |

| Package | Polybag. | Application | Automotive Houssehold Industrial. |

| Highlight | Automotive Industry Injection Plastic Mold Parts,Non Standard Injection Moulding Car Parts |

||

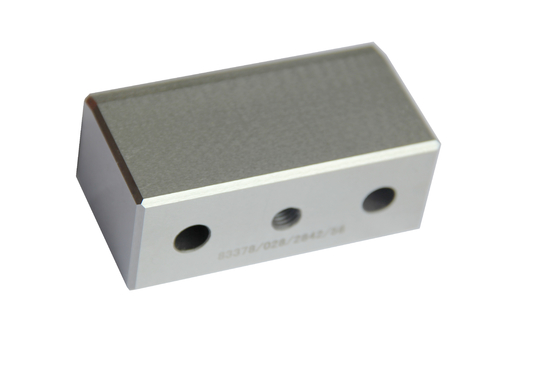

BAITO Standard Lifter For Injection Plastic Mould

Product Description

Product Name : Non-standard injection plastic mold part

| Place of Origin | Guangdong |

| Size | Non-standard |

| Shaping mode | Plastic Injection Mould |

| Feature | High precision |

| OEM | Customized |

| Package | Plastic Bag, bubble bag |

| Brand Name | BAITO |

| Product name | Non-standard injection plastic mold part |

| Brand Name | BAITO |

| QC system | 100% inspection before shipment |

| MOQ | 1 piece |

| Payment | 100% before shipment. |

| Shipping | By sea, By air, By DHL |

| Packaging | Single polybag, bubble bags, |

|

Company Advantage: |

1) Competitive factory price with good quality. 2) Low MOQ 3) 00% inspection before shipment. 4)Rich experience and good technology support 5) Short lead time . 6) Advanced measurement equipment. 7) OEM / ODM . 8) Customized size and spec in producing various kinds of precision parts). 9) Near Shenzhen and HK, convenient transportation. |

Product Show

![]()

![]()

![]()

![]()

![]()

Function of the positioning component

The positioning component is a mold accessory used to precisely lock the position between the module and the template in the plastic mold to make the mold work smoothly. The positioning component is a concave-convex combination configuration of the upper positioning block and the lower positioning block.

According to the difference of the convex positioning component, it is divided into an inclined positioning component and a right-angle positioning component. There will be a slot for more precise positioning. The positioning component is a circular main body component made of mold hot work die steel, which is composed of upper and lower sets of positioning blocks. Material: ,SKD11 Hardness: ±62HRC Standard error: ±0.001mm.

Main products

Special mold parts ( -save money and time)

Date mark insert ( -annual production is 1 million pcs)

Mould latch lock(-Good quality)

Mould slide units(hot selling worldwide)

Wear plate and guide rails(- fast delivery time)

Slide core units(hot selling worldwide)

Mold interlocks(- popular products)

Sprung core(- popular products)

Mould lifter( -ultra-precision)

Ejector pin and sleeve(cheap price)

Sprue bushing and Locating ring(stock)

Mould spring(stock)

Mould stop pin(stock)

Mould coupling(stock)

Hydraulic cylinder(High quality mold)

Collapsible Core(- the minimum diameter which we can produce is 6mm)